Key Functionalities & Benefits of Brushed Wool

Warmth & insulation

The raised fibers (nap) trap more air near the surface, increasing thermal insulation (air pockets reduce heat loss)

Makes the fabric “cozier” in cooler weather

It feels warmer “on the skin” because of the soft fuzzy surface that reduces heat escape

Soft hand / tactile comfort

The brushing gives a luxuriously soft or plush touch (a “fuzzy hand”) that improves the sensory experience of wearing the fabric

Makes garments feel more inviting and comfortable

Better drape / fuller appearance

The raised fibers can soften the visual appearance, making the fabric appear fuller, slightly more voluminous

The texture hides minor wrinkles or folds better

Moisture handling / breathability (retained wool properties)

Because the underlying wool fibers still carry their natural capabilities, brushed wool can wick moisture and remain breathable

The nap doesn’t block breathability completely in a well-engineered weave; it enhances comfort rather than undermining it

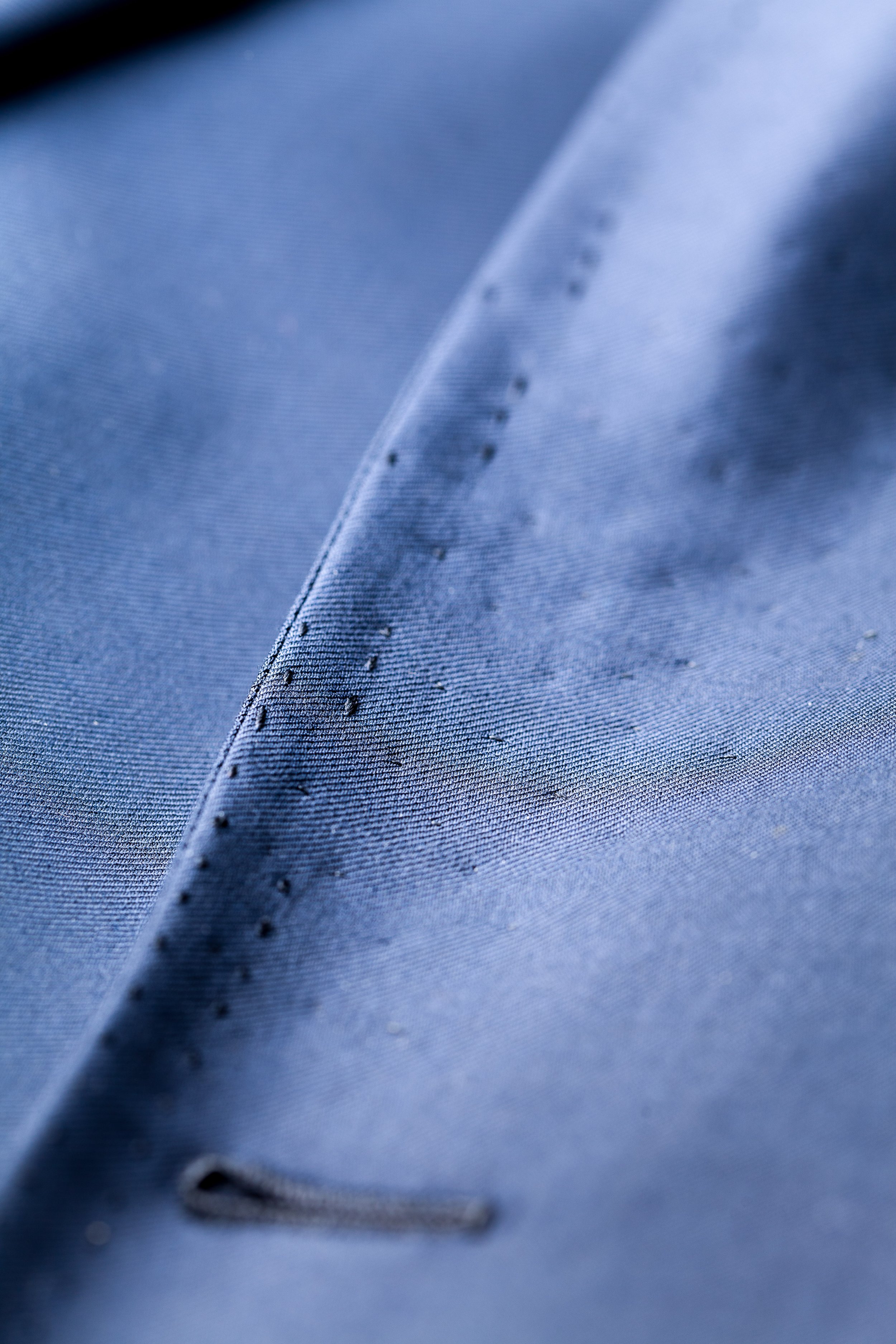

Improved visual texture / aesthetic appeal

Adds depth, richness, and tactile character to the fabric, giving it a premium look

The fuzzy surface can catch light differently, adding subtle visual interest

Better crease resistance / shape retention

Wool already has good resilience (fibers bend and spring back); the brushed finish helps mask small creases or “wear marks” thanks to the textured surface

The nap may help “hide” minor surface imperfections over time

Perceived quality & exclusivity

Because brushing is an extra finishing process, fabrics with good nap are often seen as higher quality or more luxurious

It can justify a premium in marketing and positioning

Trade-offs / things to keep in mind

Durability: The raised fibers are somewhat more vulnerable to abrasion, pilling, or wear over time (especially in high friction zones)

Maintenance: More care might be needed (brushing, careful washing, avoiding too aggressive mechanical action)

Weight / bulk: The nap can add a bit of “bulk” or thickness; more brushing / deeper nap increases this

Cost: It’s an additional finishing step, so cost is higher than plain smooth wool

Potential shedding: Initially, loose fibers might shed until the nap stabilizes

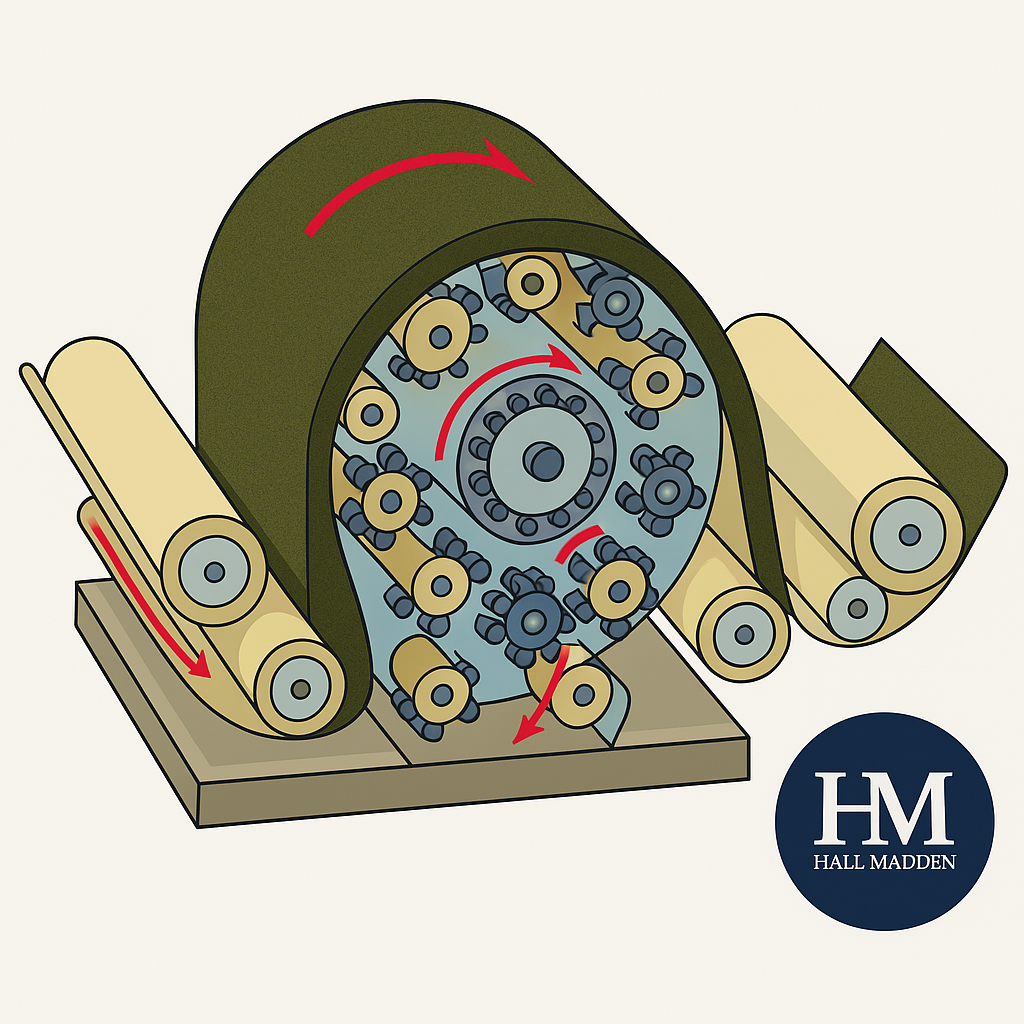

How flannel is made

Suit flannel is made by weaving wool into cloth and then brushing or “raising” the surface with fine metal rollers to lift the fibers, creating its soft, textured finish.